1. Report Overview

This report provides a comprehensive description of the material selection, performance indicators, and quality control of core hardware components (connectors, fasteners, hinges, etc.) for wood houses. As the “skeletal joints” of a wood house, the material and craftsmanship of hardware directly determine the structural stability, safety, and service life of the building. By specifying high-quality steel grades and comparing the defects of inferior materials, this report verifies the rigorous standards and safety guarantees adopted by our company in the selection of wood house hardware.

2. Core Steel Grades and Standards for Hardware Components

2.1 Main Steel Grades

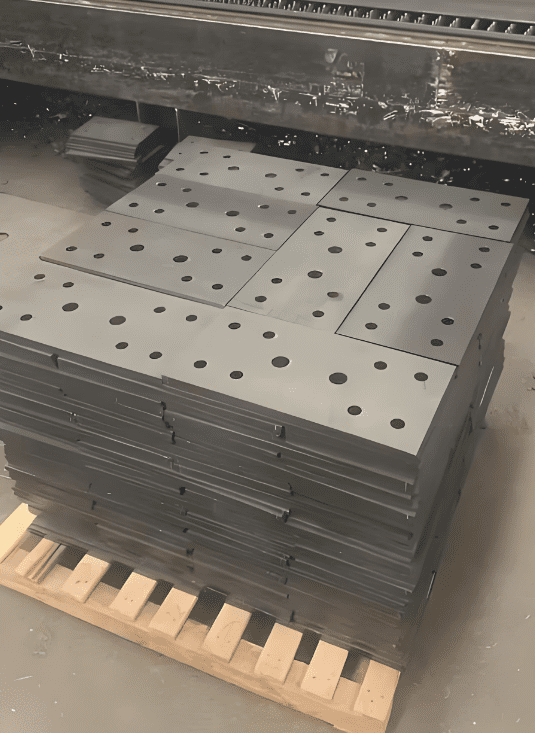

- Structural Connectors (Beam Supports, Anti-Lift Parts, Tie Bands, etc.): Adopt Q235B/Q355B hot-rolled steel strips (complying with GB/T 700-2006 standard), with carbon equivalent controlled within a reasonable range to ensure stable processing performance and structural strength. Key models include:

- HW06 Column Base Connector (6.080280mm): Q355B material, suitable for anti-lift and seismic requirements of heavy timber structures

- LD-2312 Wind-Resistant Tie Band (2351200mm): Q235B material, used for wall/floor reinforcement

- Exposed Hardware (Hinges, Handles, etc.): Adopt 304 stainless steel (complying with GB/T 3280-2015 standard) with chromium content ≥12%, featuring excellent rust and corrosion resistance.

- Auxiliary Fasteners (Bolts, Nuts): 8.8-grade high-strength carbon steel (complying with GB/T 3098.1-2010 standard) with tensile strength ≥800MPa.

2.2 Raw Material Traceability and Control

- All steel materials are directly supplied by regular steel mills such as Shougang and Angang, with each batch accompanied by material certification and zinc coating test reports (hot-dip galvanized layer thickness ≥8μm)

- Spectral analysis is conducted to verify composition before warehousing, ensuring no excessive impurities or material mixing. The welding qualification rate exceeds 99.2%

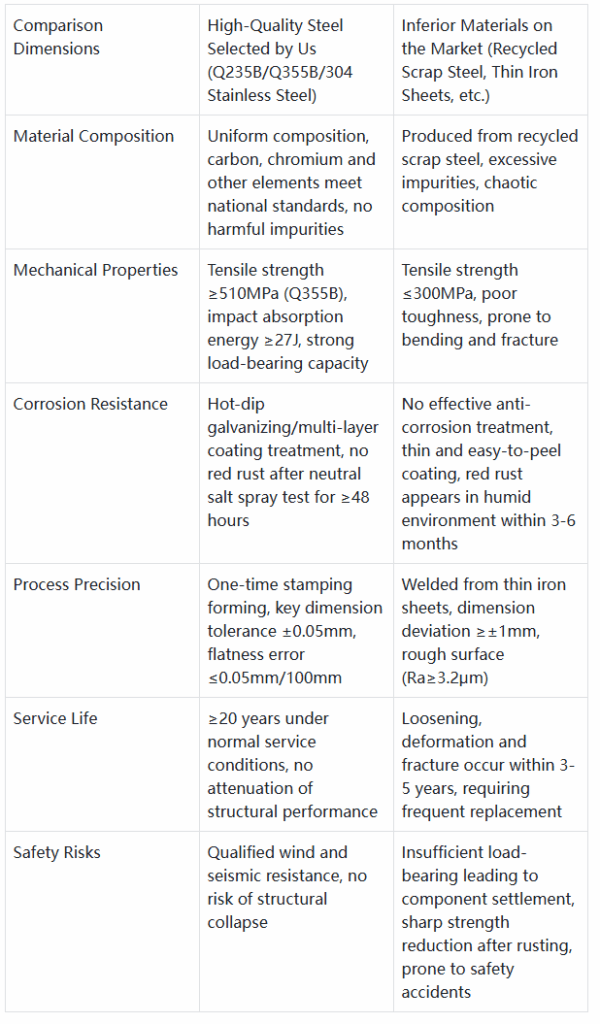

3. Core Comparison Between High-Quality Steel and Inferior Material

Key Defect Comparison Notes

- Material Defects: Inferior materials use recycled scrap steel, which is prone to cracks during welding with a welding defect rate as high as 15%; our steel materials undergo strict composition control, and the welding strength is equivalent to that of the base metal.

- Functional Failure: Inferior hinges lack effective resilience, causing cabinet doors to loosen and sag; our 304 stainless steel hinges have an opening angle exceeding 90 degrees, automatic rebound when closed to 15 degrees, and smooth and quiet operation.

- Anti-Corrosion Differences: The coating adhesion of inferior hardware is poor (peeling area ≥30% in cross-cut test); our products pass the GB/T 9286-1998 cross-cut test with peeling area <5%.

4. Quality Control System

4.1 Implementation of Inspection Standards

- Appearance Inspection: Smooth surface without scratches (length ≤5mm, depth ≤0.1mm), no pinholes (diameter ≤0.5mm), air holes or other defects

- Performance Testing:

- Tensile Test (GB/T 228.1-2010): Qualified tensile strength and yield strength

- Salt Spray Test (GB/T 10125-2012): No red rust after 48 hours

- Impact Test (GB/T 229-2007): Room temperature impact absorption energy ≥27J

- Dimensional Precision: Detected by coordinate measuring machine, key dimension tolerance complies with GB/T 1804 standard

4.2 Whole-Process Control

- Procurement: Cooperate only with qualified steel mills and suppliers, rejecting recycled materials and non-standard materials

- Production: High-frequency welding process, 5% random inspection of each batch for destructive testing

- Factory Delivery: 100% appearance inspection + 20% performance sampling inspection, accompanied by test reports and qualification certificates

5. Conclusion

By selecting high-quality steel materials such as Q235B/Q355B hot-rolled steel and 304 stainless steel, and strictly following national inspection standards, our wood house hardware comprehensively surpasses inferior materials in terms of material purity, mechanical properties, and corrosion resistance. The improved whole-process quality control system ensures that the hardware has high strength, high durability, and high safety, guaranteeing the structural stability and service life of wood house buildings from the perspective of core components. This fully reflects our company’s core principle of “rigorous material selection and safety first” in wood house manufacturing.